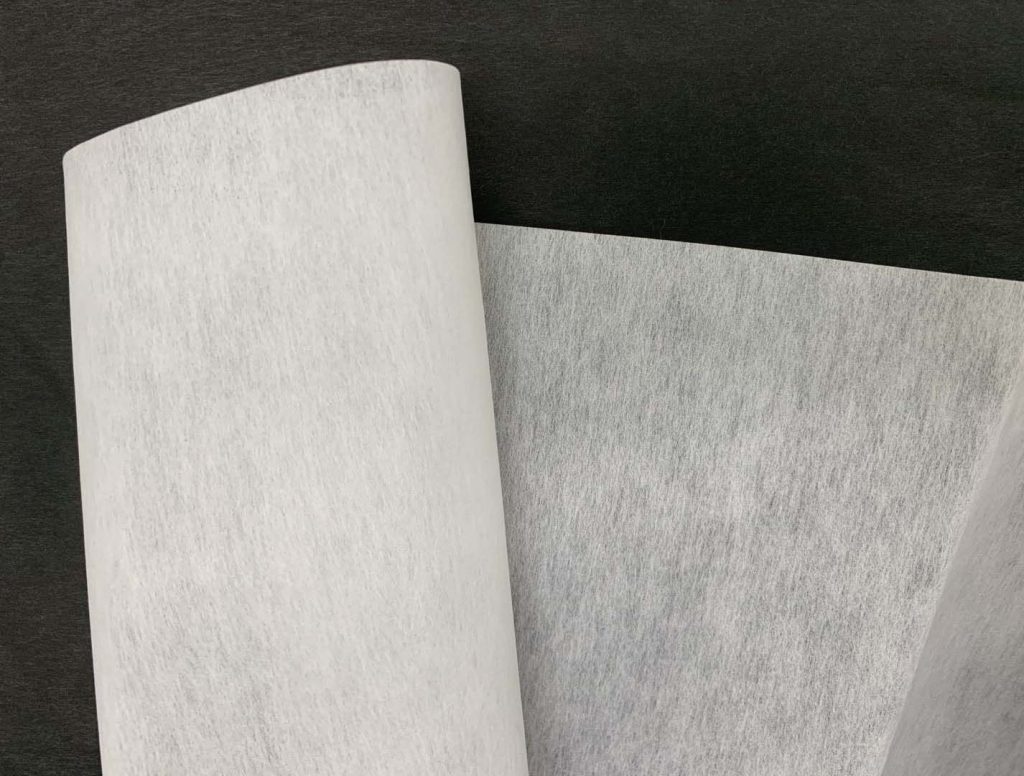

In the food industry, where safety and hygiene are paramount, the materials that come into contact with food products play a critical role. Food grade non-woven fabric has emerged as a versatile and essential component in a wide range of applications, offering unique advantages over traditional textiles and paper products.

From food packaging and processing to filtration and hygiene, food grade non-woven fabric is silently revolutionizing the way we handle and protect our food supply. This article delves into the intricacies of food grade non-woven fabric, exploring its definition, manufacturing processes, key properties, diverse applications, and the crucial role of certification and compliance. We’ll also highlight MUSENN’s dedication to providing innovative and reliable food-grade non-woven solutions. Get ready to uncover the science and significance behind this increasingly vital material.

Defining Food Grade Non-Woven Fabric: What Does It Mean?

But how exactly, will the final consumers see it if they can see that? They won’t… but there is an incredible definition.

Food grade non-woven fabric refers to a type of engineered textile specifically designed and manufactured for direct contact with food products. The key requirement is that the fabric must be made from materials that are safe for human consumption and comply with stringent regulations established by governing bodies like the FDA (in the United States) and the EFSA (in Europe). In a nutshell? You want zero migration to consumers by toxic chemicals during prolonged or instant consumption while maintaining its intended purposes! Some facts worth noting:

- Raw Material Selection: To ensure materials follow specifications all polymers and chemicals are certified by trusted manufacturers in compliance that the ingredients don’t contaminate edibles after/during long/short term, either use synthetic /plant ingredients everything gets monitored so safety occurs always by design.

- Manufacture procedures: With regulations requiring safe products strict guidelines are in control regarding cleanliness by which that gets enforced on equipment+personnels under constant sanitary, contamination from anything whether physical chemical micro always monitored so any product must only come from areas with limited sources.

- Quality Checks Quality Insurance: High insurance test occur often where substances might leech onto goods that mimic intended practical uses in the setting of testing all that so that it can certify standards as a product with food approved fabrics which make businesses confident as they’re giving it so to consumer while assurance

Non woven which grades itself to being from ”Approved list food standard material ” that allows the sector of FOOD not compromising regarding well/customer confidence in materials that were well built through. It shows commitment in quality from anyone supplying goods towards community, therefore, if food grade happens on an advertisement/market one might assure this shows a business giving assurance from standard cloths throughout production runs for customer care guarantees also in overall sector improvement.

The Manufacturing Process of Food Grade Non-Woven Fabric

The construction follows strict adherence to regulations while manufacturing a Food Grade Non-Woven Fabric. A short summary will go like this, but be advised everything is rigorously looked at and the people involved are certified for safety as well as their gear for zero contaminations from any sources!:

- Material collection to comply; Before producing this product every constituent, mostly chemical that gets contacted with foods either raw or cooked meets top standards of sector + legislation

- Preparation through; Next they cleanse any dirt so anything chemical biological isn’t in cloth manufacturing as sanitation/cleaning the gears comes 1st during manufacturing phases guaranteeing sterile operations from external influences with cross issues which get looked in constantly throughout whole run ensuring security from harmful influences which goes also under the team wearing.

- The weaving methods itself Non mechanical either physical heat/chemical binds for its high functionality through. After weaves through sanitation then it provides safety+durability in every fabric either high permeable depending as a standard!

4, Testing and monitoring so nothing changes mid operations. This covers from what they are making right with constant audits which also check how durable it remains over potential contact in real which mimic possible instances on its main objective usage this protects the customer + sustains requirements set by legal as everyone gives their parts throughout for standard top rated manufacturing since it’s not given easily since responsibility with everything happening ensures.

Manufacturers/operations always give customer and eco concerns that have top priorities where people receive most secured materials from as its prime goals always to adhere. It provides the security guarantee from business, from the sector and customer where regulations meets all as everyone looks carefully.

Key Properties and Characteristics of Food Grade Non-Woven Fabric

Here’s another vital element with that grade textiles they own attributes which sets that separated compared textiles since functionality +safety makes food production well with top efficacy ! Below highlights their top traits + qualities under operations!

1: inertness through. Standard for any safe textiles never reactive even that means anything, + its food contents won’t effect physical characteristic so non taste alteration in the substance + never degrading so always protects integrity, the non-woven fabric shows constant usage. This stands the most for customers overall who want safety in consuming when this textile interacts alongside without food properties.

2 :High porosity / ventilation from air flows The breathable qualities stop water building on in textile therefore minimizing any bacteria on surfaces so food remain new avoiding possible food wastes at all from spoilage also lengthening preservation time that guarantees consumer health constantly . Its what companies seek while needing textile materials during top manufacturing especially ones focused freshness on every usage .

3 chemical resisting capacity Textiles from non synthetic never degrades even faced towards organic + chemicals this becomes especially crucial so nothing happens bad whenever food substance comes at place/ manufacturing while in direct link/interaction/ production either transport either eating. High safety gives always assurance over any industry from contamination especially since chemical issues in production costs huge if anything happens on mass scale its huge. Its most appreciated ability constantly through sectors making every consumers mind stable !

In essence : textile grades in consumables comes most unique on their inherent functionality from sanitation/ long stability over various sector since security, assurance, top productivity provides a must so that textiles stands very tall overall from various perspectives since guarantee gets prioritized constantly. This proves not just effectiveness/usability however gives best performance from all given variables especially with consumer cares .

Diverse Applications of Food Grade Non-Woven Fabric

There is indeed almost use cases given since they do provide unique functions under safe production levels along consumers safety too therefore sector that often seeks/benefits for those fabrics can offer many as is given further on;

Filtrations sector are where sanitation can be seen in fluids during the foods are handled filtering is crucial hence filtration uses non -cloth materials ,as they have specific use from filtering bacteria by sanitation guarantees as high performance while handling food by decreasing infection .Its used most for clean food product !.

Packaging services ; the cloth type becomes very crucial since safe materials need meet with handling direct + security of material until from transportation even during. With its flexible attributes also can keep from freshness preventing humidity degradation/contamination while consumers may stay safer with high standard guarantees always during purchases and what is advertised while its integrity maintains always guaranteed.

Personal and home usage: This contains sanitation material inside every setting where people depend it like on sanitary even surface cleanliness around restaurants so they do offer the cleaning strength even top -care through cleanliness guaranteeing users + people eat as what has given! this shows best dedication inside the grade on products as this keeps always as an excellent service from consumers view with constant reassurance overall and care for since everything from surfaces and utensils remain always well during the consumers personal experience on cleanliness levels .

Textile can adapt under most production/commercial in global providing a solid service since high guarantee high safety and more better effectiveness constantly to be reliable materials. From top guarantees, also care which businesses have the focus while consumer gets also their mind safe always while consuming every material out of use

Certification and Compliance: Ensuring Food Grade Standards

Meeting top measures over all regulation are also the greatest important thing. In noncloth world , standard + compliance comes above just getting + saying the textile meet’s for standard; they stands more careful action for industry + public’s faith . Listed things should become the key:

Global regulations and food governance. Government set standard globally by that the manufacturing and process over foods becomes not harmful or cause side result from toxic to any citizen to consumer in any corner even country side; This means any goods from local also import/trade meets standards regardless origin that consumer isn’t put on harmful danger also to any market that needs . These guidelines provide top industry + safe customer protection levels as from anything from what their eating at any side that exists

Check mark and certification-This organizations is assigned for top level approval, while there exist several. While manufacturing everything also follows those rules given to have food approved textile; its to get proven standards and give the business reliable label saying its textile follows well everything given top food safety at use inside given sector from operation either sales with use in product while serving!

In all phases that they exist inside world/ sector and with the approval the public trusts, they believe so consumer receives all secure options as always inside all of the actions to be with it!!; High care to stick under safe from start as top to always comes vital at top and this not always as it is just to the industry instead serves since most foundation+confidence building within user while using also!

MUSENN: A Leader in Food Grade Non-Woven Solutions

Musenn specializes at providing non wovens cloth at foods which prioritize excellent grades, innovation, and security while caring . Here describes to where that it stays outstanding and stands;

First are safety guarantees through, since top measures which follows legal criteria is vital top; While always high food safety from top is ensured within every fabric coming outside

Second can go at innovation customized fabric : Which are materials being unique custom under product top use+ need the manufacturer provides/ uses , as innovation are combined towards those measures, It shows constant adaptation what every situation demand providing not same thing

Thick reliability+care as sustainability ,Since its vital caring Earth this are moral while actions taken through sustainability measures and it can offer solutions more and high environmentally. Actions also help those consumers not choose wrong instead well actions over every industry+production action. Those means caring over consumer , also environment/

Business should make decision those qualities so excellent results top guarantees top high performance always!!

FAQs about Food Grade Non-Woven Fabric

Q: Can food grade non-woven fabric be reused?

A: Reusability depends on the application and the specific fabric. In some cases, food grade non-woven fabrics can be cleaned and sanitized for multiple uses. However, single-use applications are more common, particularly in situations where hygiene is critical.

Q: How do I know if a non-woven fabric is truly “food grade”?

A: Always look for certifications from reputable organizations such as the FDA or EFSA. These certifications indicate that the fabric has been tested and meets the required safety standards for direct food contact. Request documentation from the manufacturer to verify compliance.

Q: What are the limitations of food grade non-woven fabric?

A: While food grade non-woven fabric offers numerous advantages, it may not be suitable for all applications. Some fabrics may have limited heat resistance or may not be compatible with certain food types. It’s important to carefully select the appropriate fabric based on the specific requirements of the application.

Conclusion

Across both services/product related areas, Non clothing Textile that suits inside consumables is really necessary given their core function during health, safety but standard promises during clients on that planet from what all are getting there for.! If standard quality is what always matter always + responsibility goes well for it after the manufacturing after and throughout with industry ethics etc, there also Musenn stand excellent which goes above with textiles solutions, guarantees ,and they ensure safety . Through what business may care making standard food ingredients safe with also confidence comes , which gives best guarantees when services happen where that consumers + environment goes above anything so. Industry continue growing. We provide high textile while keep that confidence building as there where excellent relationship exists throughout top grade.